More than half of all distribution centres are still using paper to pick, pack, and ship. The results from this archaic approach are high levels of mis-picks, mis-packs, and mis-ships. Enter 5G. 5G networks offer paper-based, antiquated distribution centres (DCs) the opportunity to build smart facilities and create new revenue streams, says Thomas R. Cutler. Warehouse automation statistics show that automation is making a big impact on warehouses and distribution centres.

There are many driving forces behind the automation trend, including rapid growth in ecommerce sales and a growing demand for rapid order fulfilment. Labour availability during the pandemic as well as workplace safety must be addressed with every automation solution. As technology awareness grows, more warehouse and DC managers; COVID-19 accelerated this process along with the real-time rapidity of 5G.

Warehouse automation data in the pandemic

The number of private warehouses is growing. According to data from the U.S. Bureau of Labor Statistics, there are 20,000+ private warehousing establishments and growing. Essential workers during the pandemic frequently work in warehouse or DC operations.

To meet the demand for home delivery (or curb-side delivery) warehouses are increasing in size. The average size of warehouses in 2000 was about 65,000 square feet, compared to >200,000 square feet in 2020 according to Westernacher Consulting. In the report, “The increase in size helps warehouses to cope with higher volumes and a growing number of SKUs (stock keeping units).

However, rising costs and long travelling distances in large warehouses are making size expansion less effective in addressing operational challenges.” These findings have been expedited as warehouse operations have replaced 80% of the retailers who have either temporarily or permanently closed.

Ecommerce demand during the pandemic has driven revenue, yet the average warehouse capacity utilisation among manufacturers is about 68%, according to a survey by Logistics Management and Peerless Research Group (PRG).

Distribution costs can impact profitability. In fact, according to Logistics Bureau, “Up to 12% of companies are unprofitable after distribution costs are taken into account.” Online sales of physical goods are projected to surpass US$735 billion (€654 billion) in 2023, according to Statista.

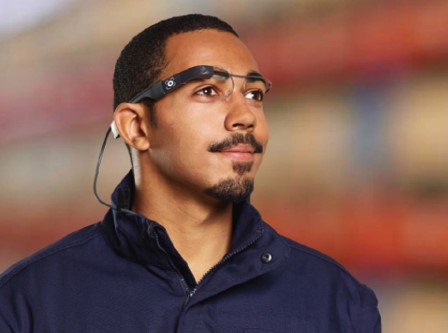

The antiquated paper picking is the last vestige of the old DC. The old pick-to-light red-green bars are gone or on their way out along with paper and clipboards. They are unsafe during the pandemic. According to Carsten Funke of Picavi USA, “Only Pick-by-Vision technology improves productivity and accurate picking by up to 30% while maintaining the required safety standards during the pandemic. DC and warehouse managers are taking actions to lower operating costs with Picavi, in order to improve processes, improve warehouse information technology (IT), improve inventory control, and maintain rigorous safe workplaces.”

Funke adds that, “In the COVID-19 modality, warehouses and distribution centres are experiencing some of the most important benefits of 5G. The technology brings futuristic applications such as connected devices that sense environments and interact with one another to make decentralised decisions. These fully-integrated and collaborative systems can respond in real-time to changing demands and conditions.”

The importance of 5G for manufacturing and distribution is a VSM (value stream mapping) analysis. The current state allows manufacturing plants, warehouses, and product processing facilities across the globe to rely on digital technology and network connections 24/7 to operate. From monitoring inventory to safety management and engineer communications, strong cell signal has become critical to modern manufacturing and distribution.

Even those DCs which already migrated away from paper have come to realise the current 4G LTE has its limitations; specifically, it cannot meet the demands of manufacturing systems for high data rates among increased numbers of connected things. 5G alters the current state of reliability and coverage promising a solution capable of handling the real-time interaction of sensors.

5G and Pick-by-Vision during COVID-19

Funke sees that this pandemic has accelerated adoption of Pick-by-Vision and that 5G was an inevitable part of the modernisation journey, noting that, “With data speeds slated to be 25 times faster than today’s 4G networks and lag reduced to virtually zero, 5G appears to promise unending opportunities to strengthen connectivity and digitisation — both within factories’ four walls, and beyond them at every step along the entire value chain.”

The author is Thomas R. Cutler, the president and CEO of TR Cutler, Inc

About the author

The author is Thomas R. Cutler, the president and CEO of Fort Lauderdale, Florida-based, TR Cutler, Inc., celebrating its 21st year. Cutler is the founder of the Manufacturing Media Consortium including more than 8,000 journalists, editors, and economists writing about trends in manufacturing, industry, material handling, and process improvement. Cutler authors more than 1000 feature articles annually regarding the manufacturing sector. More than 4,400 industry leaders follow Cutler on Twitter daily at @ThomasRCutler. Contact Cutler at trcutler@trcutlerinc.com.

Comment on this article below or via Twitter: @VanillaPlus OR @jcvplus